Product description

Synonym for experience and safety

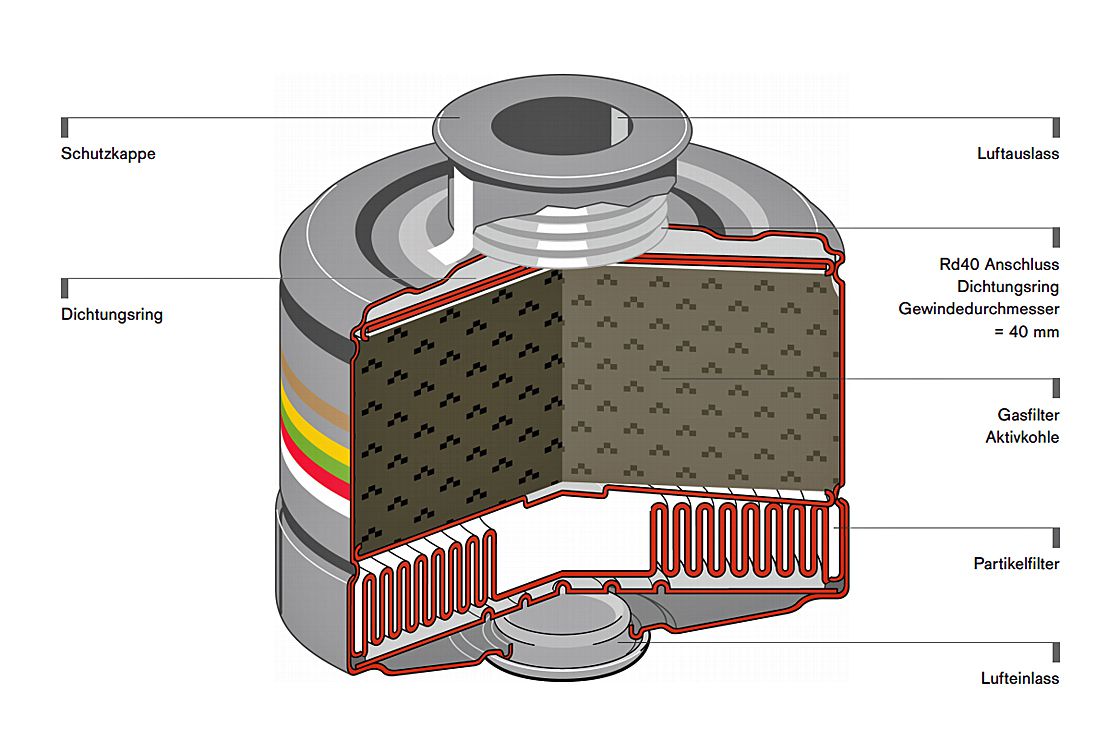

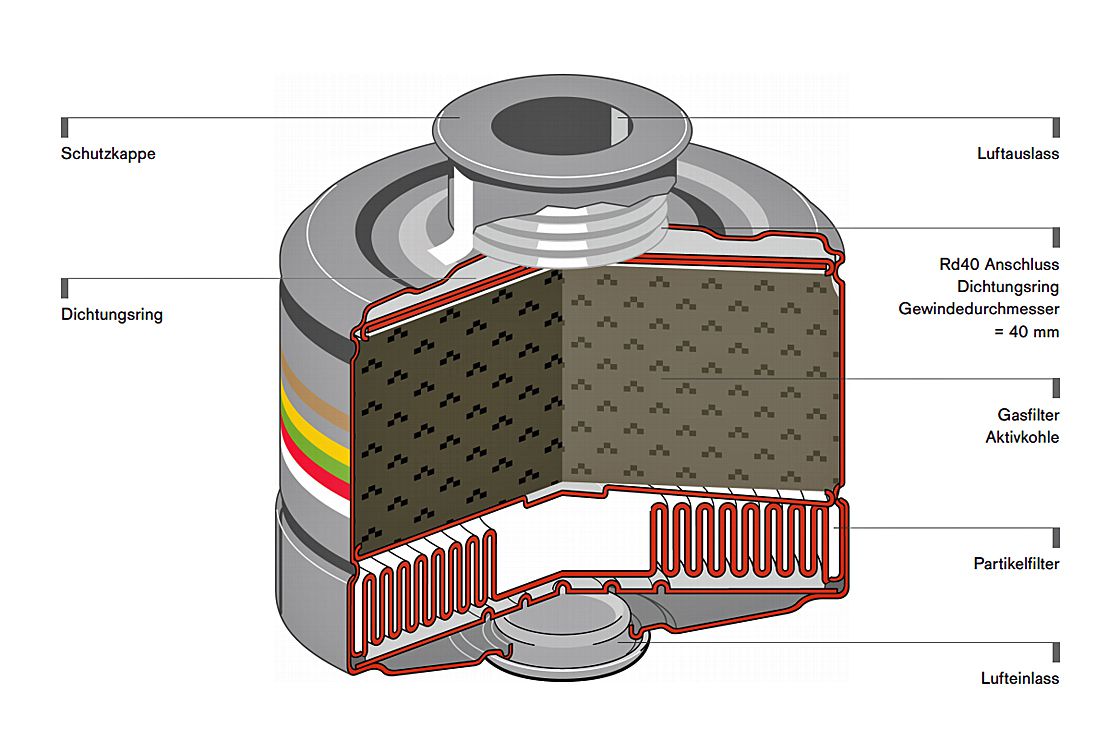

The quality filters of the Dräger X-plore® Rd40 series clean the breathing air of pollutants economically and effectively - whether in the chemical or automotive industry, in shipbuilding, in metal working and processing or in supply and disposal. Suitable for masks with standard round thread Rd40 (RA) according to EN 148-1.

The gas and combination filters have a shelf life of 6 years, the particle filters of 12 years from the date of manufacture.

The filters are individually packaged to ensure optimum protection of the unused filter. The packaging is resealable for longer use.

The aluminium housing allows for good visibility of possible filter damage for added safety.

Wide application range

The Dräger filter series X-plore Rd40 with standardised round thread according to EN 148-1 has proven itself many times in practice and offers decisive advantages:

- Extensive range of various filter types for all essential areas of application

- suitable for half and full face masks with connection according to EN 148-1

High user safety

- CE certified (EN 141:2000, EN 14387, EN143:2000, EN 371)

- comprehensive filter selection aid programme VOICE

- detailed information leaflets

- filters with aluminium housing with good visibility of possible filter damage

- over 70 years of experience in filter technology

High economic efficiency

- individually packed for best protection of the unused filter (incl. instructions for use)

- resealable for longer use

- Shelf life (from date of manufacture):

? Gas and combination filters = 6 years

? Particle filter = 12 years

How do I find the right filter?

Pollutants can occur in different forms, as aerosols (particles or droplets), as gases or vapours. Depending on the form, you need to protect yourself against one of these types or a mixture of them.

? Aerosols (particles): Dusts, fibres, fumes, microorganisms (e.g. viruses, bacteria, fungi and their spores) and mists.

? Gaseous substances: gases or vapours

The following table shows the colour coding of the filters according to EN 14387, which will help you to choose the right type of filter for use against your pollutant.

individually packed for best protection of the unused filter (incl. instructions for use)

- resealable for longer use

- Shelf life (from date of manufacture):

? Gas and combination filters = 6 years

? Particle filter = 12 years

Values and calculations have been taken from EN529:2005 and BGR 190. Other national or local regulations must be observed. AGWs were taken as the limit values here. Here, the time-weighted average values over a reference period apply and no short-term limit values.

AX-Filter may only be used in the condition in which they were delivered (fresh from the factory). Reuse and use against gas mixtures is absolutely prohibited.

CO-Filter may only be used once and must be disposed of after use. Instructions according to local guidelines must be followed.

Hg-Filter may only be used for a maximum of 50 hours according to EN14387.

NO-Filter may only be used once and must be disposed of after use.

Reaktor-Filter Instructions according to local guidelines must be followed.

Differentiation of filter types

Filters are divided into different classes according to their capacity (gas filters) or their efficiency (particle filters). Class 2 gas filters may be used at higher concentrations or for longer periods than class 1 filters. The class of particle filters indicates how efficiently the filter filters particles out of the ambient air (class 1: 80 %, class 2: 94 %, class 3: 99.95 %).

Filtertyp | Filterklasse | Schutz gegen | Höchstzulässige Schadstoffkonzentration |

Gasfilter | Gase und Dämpfe | ||

Kapazität: | 30 x Grenzwert mit Halbmasken / 400 x Grenzwert mit Vollmasken, jedoch maximal: | ||

1 | klein | 0,1 Vol.-% (1.000 ppm)* | |

2 | mittel | 0,5 Vol.-% (5.000 ppm)* | |

3 | groß | 1,0 Vol.-% (10.000 ppm)* | |

Partikelfilter | Partikeleffizienz (Abscheideleistung | ||

1 | klein | 4 x Grenzwert** | |

2 | Mittel | 10 x Grenzwert mit Halbmasken / 15 x Grenzwert mit Vollmasken** | |

3 | groß | 30 x Grenzwert mit Halbmasken / 400 x Grenzwert mit Vollmasken** | |

Beispiel: Bleistaub MAK = 0,1 mg/m3 4 × 0,1 mg/m3 = 0,4 mg/m3 = max. erlaubte Konzentration von Bleistaub beim Gebrauch von P1-Filtern. | |||

Technical data

- Manufacturer: Drägerwerk AG & Co. KGaA, Moislinger Allee 53-55, DE-23558 Lübeck, info@draeger.com

- Responsible Person: Drägerwerk AG & Co. KGaA, Moislinger Allee 53-55, DE-23558 Lübeck, info@draeger.com

Product description

Synonym for experience and safety

The quality filters of the Dräger X-plore® Rd40 series clean the breathing air of pollutants economically and effectively - whether in the chemical or automotive industry, in shipbuilding, in metal working and processing or in supply and disposal. Suitable for masks with standard round thread Rd40 (RA) according to EN 148-1.

The gas and combination filters have a shelf life of 6 years, the particle filters of 12 years from the date of manufacture.

The filters are individually packaged to ensure optimum protection of the unused filter. The packaging is resealable for longer use.

The aluminium housing allows for good visibility of possible filter damage for added safety.

Wide application range

The Dräger filter series X-plore Rd40 with standardised round thread according to EN 148-1 has proven itself many times in practice and offers decisive advantages:

- Extensive range of various filter types for all essential areas of application

- suitable for half and full face masks with connection according to EN 148-1

High user safety

- CE certified (EN 141:2000, EN 14387, EN143:2000, EN 371)

- comprehensive filter selection aid programme VOICE

- detailed information leaflets

- filters with aluminium housing with good visibility of possible filter damage

- over 70 years of experience in filter technology

High economic efficiency

- individually packed for best protection of the unused filter (incl. instructions for use)

- resealable for longer use

- Shelf life (from date of manufacture):

? Gas and combination filters = 6 years

? Particle filter = 12 years

How do I find the right filter?

Pollutants can occur in different forms, as aerosols (particles or droplets), as gases or vapours. Depending on the form, you need to protect yourself against one of these types or a mixture of them.

? Aerosols (particles): Dusts, fibres, fumes, microorganisms (e.g. viruses, bacteria, fungi and their spores) and mists.

? Gaseous substances: gases or vapours

The following table shows the colour coding of the filters according to EN 14387, which will help you to choose the right type of filter for use against your pollutant.

individually packed for best protection of the unused filter (incl. instructions for use)

- resealable for longer use

- Shelf life (from date of manufacture):

? Gas and combination filters = 6 years

? Particle filter = 12 years

Values and calculations have been taken from EN529:2005 and BGR 190. Other national or local regulations must be observed. AGWs were taken as the limit values here. Here, the time-weighted average values over a reference period apply and no short-term limit values.

AX-Filter may only be used in the condition in which they were delivered (fresh from the factory). Reuse and use against gas mixtures is absolutely prohibited.

CO-Filter may only be used once and must be disposed of after use. Instructions according to local guidelines must be followed.

Hg-Filter may only be used for a maximum of 50 hours according to EN14387.

NO-Filter may only be used once and must be disposed of after use.

Reaktor-Filter Instructions according to local guidelines must be followed.

Differentiation of filter types

Filters are divided into different classes according to their capacity (gas filters) or their efficiency (particle filters). Class 2 gas filters may be used at higher concentrations or for longer periods than class 1 filters. The class of particle filters indicates how efficiently the filter filters particles out of the ambient air (class 1: 80 %, class 2: 94 %, class 3: 99.95 %).

Filtertyp | Filterklasse | Schutz gegen | Höchstzulässige Schadstoffkonzentration |

Gasfilter | Gase und Dämpfe | ||

Kapazität: | 30 x Grenzwert mit Halbmasken / 400 x Grenzwert mit Vollmasken, jedoch maximal: | ||

1 | klein | 0,1 Vol.-% (1.000 ppm)* | |

2 | mittel | 0,5 Vol.-% (5.000 ppm)* | |

3 | groß | 1,0 Vol.-% (10.000 ppm)* | |

Partikelfilter | Partikeleffizienz (Abscheideleistung | ||

1 | klein | 4 x Grenzwert** | |

2 | Mittel | 10 x Grenzwert mit Halbmasken / 15 x Grenzwert mit Vollmasken** | |

3 | groß | 30 x Grenzwert mit Halbmasken / 400 x Grenzwert mit Vollmasken** | |

Beispiel: Bleistaub MAK = 0,1 mg/m3 4 × 0,1 mg/m3 = 0,4 mg/m3 = max. erlaubte Konzentration von Bleistaub beim Gebrauch von P1-Filtern. | |||

Technical data

- Manufacturer: Drägerwerk AG & Co. KGaA, Moislinger Allee 53-55, DE-23558 Lübeck, info@draeger.com

- Responsible Person: Drägerwerk AG & Co. KGaA, Moislinger Allee 53-55, DE-23558 Lübeck, info@draeger.com